Design and construction of modular units for delivery to client’s site.

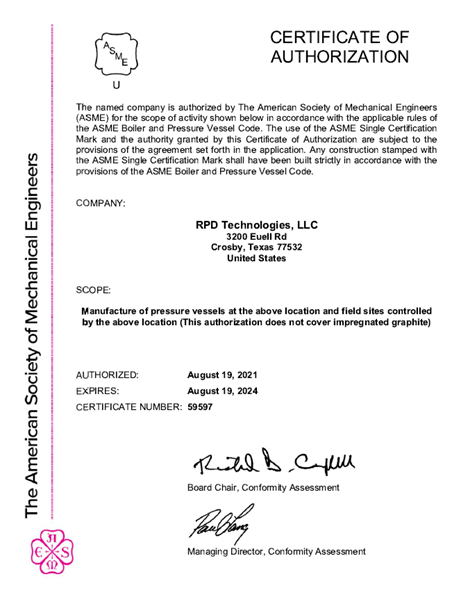

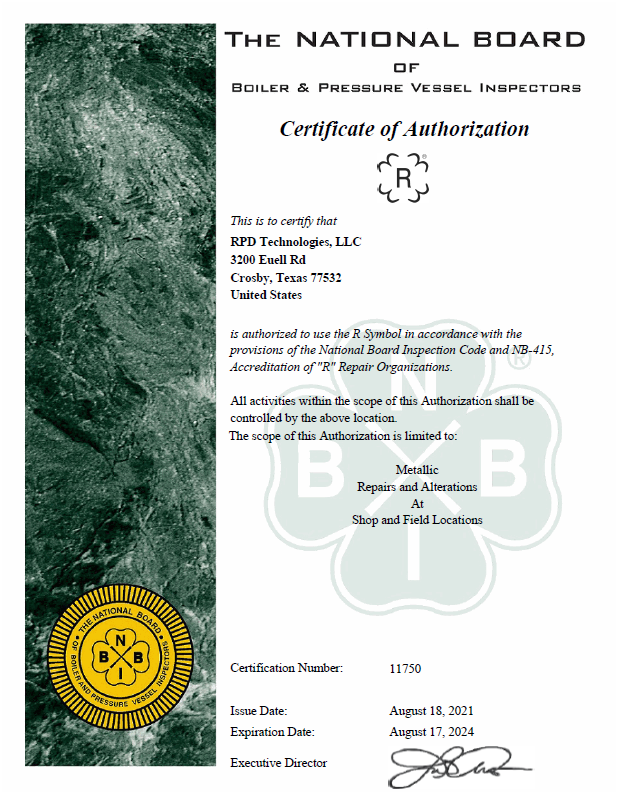

Mechanical Fabrication

Capabilities include ASME pressure vessel and Heat Exchanges fabrication, specialized equipment like reactors, vessel internals and piping. All the design, calculations and analysis are performed in-house to ensure full mechanical integrity at maximum operating conditions through out the expected life cycle of the equipment. RPD holds U and R stamps for shop and field services for Section VIII Division 1 pressure vessels and heat exchangers fabrication and repair.

Process Engineering

Process Engineering capabilites include performing process simulation, developing heat and material balance, creating PFD’s and P&IDs, equipment and instrument sizing, preparing system package specifiation, preparing control narratives, perform PHAs.

Electrical and Controls

RPD designs and builds electrical cabinets, marshalling panels, and other electrical sub-panels in-house. Sizing, installation and testing of electrical components and assembly follows proper NFPA, UL and other applicable codes and standards. Control system capabilities include programming PLCs and creating HMIs locally and developing full SCADA system for control, monitoring, and data acquisition.

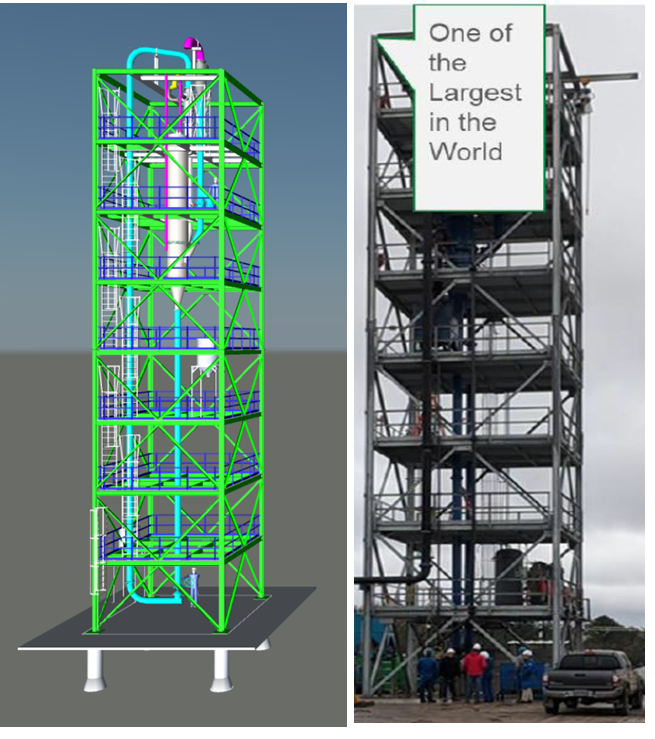

Turnkey Solutions

RPD has all the capabilities to design and deliver turnkey solutions to our customers and for internal use. A full 3D general arrangement model of the unit is created for every project which allows ease of review by various teams including design, fabrication, maintenance, and operations teams before beginning of fabrication. Units are fully tested according to stringent testing and quality assurance protocols. Testing includes but not limited to pressure test, wiring continuity test, instrument loop check, controls functionality testing and testing with inert materials or hydrocarbons where possible before handing the unit to operations or shipping it out.